Listen to this blog

Best Practices for Farm to Table Traceability

Unlocking seamless safety: transform farm-to-table traceability with BL.INK’s GS1 Digital Link solution

In today's rapidly-evolving food industry, traceability is a fundamental cornerstone of operation for large-scale producers. The ability to master every step of farm to table traceability is essential for meeting stringent safety regulations and ensuring the highest standards of quality and compliance. As recent events have shown, the repercussions of recalls can be devastating, both financially and for the consumer’s trust.

Enter BL.INK’s GS1 Digital Link solution, a game-changer in the realm of digital farm to table traceability. This innovative technology offers a seamless, integrated approach that minimizes the risks and costs associated with product recalls. By enabling real-time tracking and management of product information across the entire supply chain, BL.INK enhances operational efficiency and fortifies the bond of trust with consumers. Read on to learn how leveraging cutting-edge technologies like GS1 Digital Link can transform the landscape of food safety and transparency in the industry.

Let's delve into the specifics of this transformative solution and explore how it can bring about a revolutionary change in the way large-scale food producers operate.

What is GS1 Digital Link?

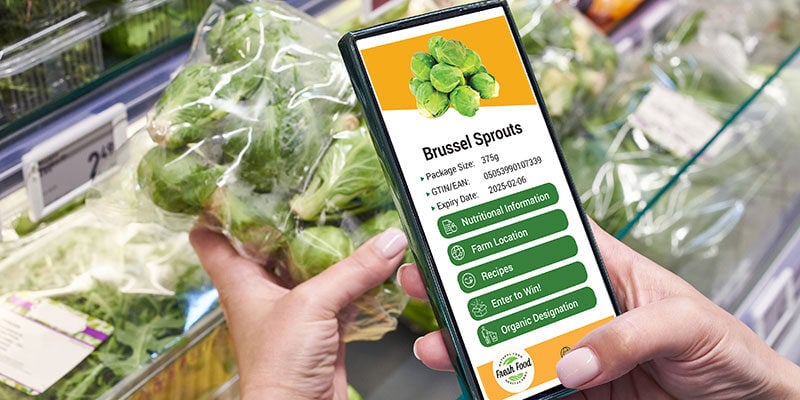

By the end of 2027, QR codes or 2D barcodes—referred to as GS1 Digital Links—will replace the traditional one-dimensional barcode on all consumer packaging. While many food producers use QR codes throughout their processes today for various reasons, GS1 Digital Links from BL.INK enable you to use just one QR code on a package for cross-functional uses, including checkout at the point of sale. BL.INK can integrate with any data source to deliver real-time, relevant information based on who scans the code. Watch our webinar about GS1 Digital Link.

Traceability Empowerment

Understanding the fundamentals of farm to table traceability in the food industry is akin to putting together a complex puzzle where every piece is essential for the complete picture of food safety. At BL.INK, we recognize how crucial it is for producers to monitor every aspect of a product's journey, from the farm right to the consumer's table. This is where our GS1 Digital Link solution for food production comes into play, seamlessly integrating with your existing systems to offer real-time data capture and monitoring.

Imagine a mid-sized farm that's been managing its farm to table traceability manually. Transitioning to BL.INK’s solution, they start by tagging each batch of produce with a unique, digital identifier that can be tracked through every phase of its journey. This digital upgrade allows them not only to trace the path of their produce but also to share this information with distributors, retailers, and even consumers in real-time.

The impact? When an issue arises—say, a possible contamination in a batch of tomatoes—it’s easy to pinpoint the affected produce's exact location quickly, preventing further distribution and reducing health risks. What’s more, because our solution captures and shares all data in real time, the farm also benefits from complete transparency and easy access to historical data. This data isn't just a pathway to resolving immediate issues—it’s a treasure trove of insights that can help optimize processes and make informed decisions driven by data, not guesswork.

Moreover, the BL.INK system is designed to be user-friendly. There's no need for extensive technical training or major disruptions to existing setups. It's a plug-and-play solution that integrates with your current technological infrastructures, making data sharing smooth and straightforward. This ease of adoption ensures that even farms not traditionally tech-savvy can leverage the benefits of advanced traceability technologies.

For businesses in the food production industry, adopting such an integrated traceability system is not just about compliance or preventing mishaps; it's about taking proactive steps towards a more efficient, transparent, and safe food supply chain. With BL.INK, you’re not just investing in technology; you’re investing in peace of mind, knowing that you can efficiently manage and mitigate risks no matter how large your operation grows.

Empowering Traceability

Exploring the innovative features of the GS1 Digital Link solution reveals its ability to transform farm to table traceability with tools designed for safety and efficiency.

Real-time data tracking stands out as a game changer. It enables food producers to monitor their products throughout the supply chain instantaneously. Imagine a scenario where a batch of berries from a supplier is flagged for potential pesticide levels. With real-time data tracking, the food producer can quickly trace the batch back to its source, identify all products that may be affected, and prevent them from reaching the consumer—all in real time.

Dynamic product microsites are another key feature. These are tailored web pages linked to each product through a QR code, providing consumers with rich details about the product's origin, processing, and more. This not only boosts consumer confidence but also enhances regulatory compliance by ensuring all information is just a scan away. BL.INK enables you to share unique experiences based on who is scanning the QR code, their location, and even their preferred language, delivering up-to-the-minute data in real time upon scan.

Consider a fictional food producer, Lakeside Organics. They’ve adopted the GS1 Digital Link solution and, on one occasion, a consumer queries about the organic status of their apples. By scanning the QR code, the consumer accesses a microsite detailing the apples’ journey from the orchard, organic certification, to the store. This level of transparency fosters immense trust and puts Lakeside at a competitive advantage.

By utilizing these features, food producers not only streamline their operations but also build a stronger, trust-based relationship with consumers. In doing so, they set new standards in the food industry for reliability and consumer satisfaction. Adopting such technologies positions food and beverage brands at the forefront of the food industry's future, where safety, transparency, and efficiency lead the way.

Brand Empowerment

Adopting advanced farm to table traceability technologies like GS1 Digital Link elevates a food brand's reputation and builds stronger relationships with consumers by ushering in an era of transparency in food production. In today’s market, consumer trust is not just a nice-to-have, but a crucial pillar of a successful brand. Consumers are increasingly interested in the origin and safety of their food, and they appreciate brands that provide that information readily.

Consider a food brand that recognizes the importance of transparency and decides to integrate GS1 Digital Link into their operations. Before the change, they had minimal visibility into their own supply chain, which occasionally led to delays in addressing quality issues and resulted in periodic recalls. With GS1 Digital Link, they transformed their approach. Now, each product carries a QR code that offers consumers and regulators real-time access to the food’s journey from the farm right to the supermarket shelf.

This capability enhanced their operational efficiency and significantly bolstered consumer confidence. Sales data showed a noticeable improvement after the implementation. Consumers were reassured by the open access to product history, and this trust was reflected in their purchasing choices. Regulatory compliance, too, saw a marked improvement, as auditors could easily verify the product journey and safety standards compliance at any point.

Moreover, the implementation of such technology sets a new industry standard. Brands that embrace these advancements are seen as pioneers and leaders, showing a commitment to safety and quality that goes beyond the minimum regulatory requirements. It sets a competitive benchmark that pressures the entire industry to elevate its standards of operation.

The forward-thinking adoption of GS1 Digital Link by a food brand showcases how technology cannot only solve immediate operational challenges but also strategically position a company for long-term success and industry leadership. In an industry as dynamic as food production, staying ahead of technological trends is not just beneficial but essential for maintaining consumer trust and regulatory compliance.

Visit BL.INK today to revolutionize your product traceability and take the first step towards a safer, more transparent future.

Ready to take your farm to table traceability to the next level? Our GS1 Digital Link technology puts cutting-edge tools at your fingertips, revolutionizing how you monitor and manage your products from farm to table. This isn't just about keeping up with regulations—it's about setting a new standard in food safety and transparency that your customers will notice and appreciate. Visit the BL.INK website today to find out how our solutions can protect your products, enhance your brand, and build lasting trust with your consumers. Let's start a conversation about a safer, more transparent future.

Frequently Asked Questions

Many decision-makers in the food industry often question the technical requirements, the process of integrating with existing systems, and the timeline for realizing the benefits of new traceability systems. Let’s address these valid concerns.

What are the technical requirements for implementing a traceability system like GS1 Digital Link?

You'll be glad to know that transitioning to our system does not mean an overhaul of your current setup. Our technology is designed to be plug-and-play, ensuring it integrates smoothly with your existing software and hardware. This integration leverages standard APIs and can typically be managed by your in-house IT team or with minimal support from our tech specialists.

How does this integration process work with existing systems?

Integration is seamless and straightforward. After a preliminary system audit to understand your current processes, our team outlines a clear step-by-step implementation plan. This plan includes minimal disruption to your ongoing operations, ensuring you can maintain productivity while upgrading your systems.

How quickly can you expect to see benefits after implementation?

BL.INK offers the fastest time-to-value of any GS1 Digital Link solution provider. Once your systems are connected via our straightforward API, you can share data and see improvements in operational efficiency almost immediately after the system goes live. Benefits like enhanced product traceability, reduced risk of recalls, and increased consumer confidence become evident within the first few months post-implementation. These enhancements are not just about compliance; they're about revolutionizing how you engage with consumers and oversee your supply chain, making transparency and safety your top priority. Our solution offers the robustness large-scale operations require without the complexity that often accompanies new technology installations. By simplifying the technical side and focusing on user-friendly features, we help you protect your brand and build stronger trust with your customers.

Not sure where to start with GS1 Digital Link? Let's do a totally-free workshop for your team. Or set a time to get a demo of BL.INK's GS1 Digital Link solution.