Listen to this blog

How One QR Code on Food Packaging Revolutionizes Processes

Navigating the complexities of large-scale food production requires a smart, streamlined approach, especially when balancing efficiency with rigid safety standards. Innovative packaging can preserve the quality of products and fortify consumer trust and compliance. One such groundbreaking solution is the GS1 Digital Link solution offered by BL.INK, which transforms conventional packaging into a gateway of real-time data and consumer interaction.

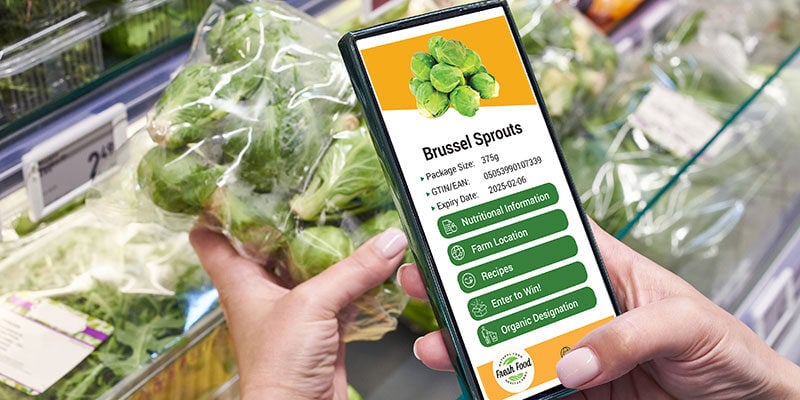

In the modern food industry, the challenges of managing extensive supply chains include ensuring absolute traceability, maintaining consistent quality, and meeting diverse global compliance requirements. It's crucial for companies to adopt tools that enhance operational efficiencies while also addressing these rigorous standards. By using BL.INK to integrate GS1 Digital Link into packaging strategies, food producers get a validated GS1 link, a durable QR code (down to the serial number, if needed), and a no-code, dynamically created product microsite that delivers real-time information upon every scan. With BL.INK, you can use one QR code on food packaging to link data about every product, up and down the supply chain, through the entire product journey and the customer lifecycle. This technology not only simplifies data management across different markets but also provides a platform for consumer engagement directly through the QR code on food packaging, thereby enhancing trust and loyalty.

How Product Digitization Impacts Crisis Aversion

Imagine a scenario where a large-scale food production company faces a critical recall situation. Thanks to implementing real-time data tracking with BL.INK's GS1 Digital Link/2d barcode solution: they were able to act swiftly. As soon as the issue was detected, updates were pushed out across all packaging platforms, instantly informing distributors, retailers, and consumers about the recall. This rapid response not only minimized health risks but also limited operational disruptions and preserved consumer trust.

BL.INK's Dynamic Product Microsites and GS1 Digital Link solution empower companies to act quickly, with a clarity that was previously unattainable—transforming every package into a gateway for essential, actionable data. Managers can now pinpoint the exact location and status of any item in real-time, drastically reducing the confusion and time typically associated with recall events.

In summary, integrating BL.INK’s QR code on food packaging and logistical operations bridges the gap between real-time data access and effective supply chain management. It assures not just compliance with safety standards but enhances consumer confidence through dedicated engagement and robust data deployment. This approach not only streamlines management but turns potential crises into manageable bumps in the road, proving indispensable in modern food production and distribution frameworks.

GS1 Digital Link and Proactive Compliance

Structured data is transforming how companies manage their supply chains, making processes more proactive and efficient. By integrating comprehensive analytics into their operations, businesses can preemptively identify potential disruptions and compliance issues, addressing them before they escalate into larger problems.

Take, for example, a scenario where a batch of ingredients suspected of contamination enters a food production line. With structured data collected through advanced digital tools like GS1 Digital Link offered by BL.INK, the management team can quickly trace the batch's journey across the supply chain. This real-time insight allows for immediate action—removing the affected products and preventing them from reaching consumers, thereby safeguarding public health and the company's reputation.

This level of detail not only enhances operational transparency but also improves collaboration among all stakeholders. Suppliers, distributors, and retailers can share data seamlessly, fostering a unified approach to problem-solving and compliance. This shared data environment supports a collective responsibility ethos, crucial for maintaining product quality and safety standards across the board.

The benefits of structured data extend to compliance as well. Regulatory requirements in the food industry are stringent and ever-evolving. Detailed analytics help companies stay ahead of these changes, ensuring that all products meet the latest safety standards before they reach the market. This proactive compliance is vital for maintaining consumer trust and brand integrity.

Furthermore, the integration of structured data enables companies to better analyze trends and patterns, leading to more informed decision-making. This data-driven approach not only streamlines supply chain operations but also enhances strategic planning, helping companies anticipate market shifts and adapt swiftly.

In embracing digital tools like GS1 Digital Link via QR codes on food packaging, companies are not merely reacting to industry challenges but are proactively managing them. This empowers businesses to turn potential crises into opportunities for reinforcing trust and compliance—key factors in a competitive, consumer-focused market. By leveraging structured data, large-scale food production companies can ensure a smoother, more responsive supply chain that is not only compliant but also aligned with future industry developments and consumer needs.

BL.INK Integrates with Complex Existing Processes

For a food production giant, managing compliance and operational efficiency is already a complex juggling act. BL.INK's solutions are designed to fit smoothly into your current workflow, including Esko WebCenter, maintaining adherence to rigorous GS1 standards and enhancing overall system efficacy.

Imagine you're rolling out a new line of packaged foods that require strict temperature controls during shipping. By incorporating GS1 Digital Link through BL.INK's technology, each package not only carries standard barcode information but also detailed, real-time data about storage conditions, batch numbers, and expiration dates. This data is crucial for ensuring quality control and can be accessed with a simple scan of the QR code on food packaging, streamlining the process for quality assurance teams and supply chain managers.

The first step is a simple evaluation of your existing packaging and IT infrastructure, followed by a strategic implementation plan that respects and enhances these systems. BL.INK’s technology seamlessly incorporates into your current operations without the need for disruptive overhauls. This smooth integration encourages swift adoption and minimal training requirements, reducing downtime and accelerating the realization of benefits.

Moreover, our solutions facilitate ease in updating product information digitally, which is crucial for compliance and consumer safety. Changes to compliance data or product details are instantly updated across all platforms, ensuring everyone in the supply chain, including consumers, has access to the most current and accurate product information.

The end result is a digital transformation of your packaging strategy, turning every package into a dynamic data hub that increases traceability, enhances safety, and builds consumer trust—all while ensuring your operations align with global standards. By leveraging BL.INK's technologies, you not only meet today's demands but also prepare for future regulatory changes and market expectations, keeping you steps ahead in a competitive industry.

Thus, enhancing your systems with BL.INK isn’t just about keeping up; it’s about setting a new standard, ensuring every product you ship meets the high standards both you and your customers expect. This kind of forward-thinking solution not only protects your brand but also propels it into the future of food safety and consumer interaction.

Frequently Asked Questions

How can the GS1 Digital Link solution elevate your existing packaging processes?

This cutting-edge technology seamlessly embeds a wealth of traceable data into your product packaging, simplifying compliance and improving safety. By utilizing QR codes, GS1 Digital Link can enable direct access to product information, making it an indispensable tool for traceability and consumer engagement.

What are the advantages of real-time data access in packaging?

Real-time data tracking access you're always informed about where your products are and how they're performing. This instant access to data helps in making swift decisions, particularly vital in recall situations or when compliance issues arise. It reinforces consumer trust as they gain access to real-time, transparent product information.

How does BL.INK’s GS1 Digital Link solution integrate with existing systems?

Integration is smooth and straightforward. GS1 Digital Link integrates with your current systems via API to connect information across the supply chain without complicating existing workflows. This integration supports GS1 compliance and enhances efficiency, saving you time and resources while ensuring your operations meet global standards.

What operational benefits does BL.INK’s GS1 Digital Link solution offer?

By turning each package into a data hub, BL.INK offers unparalleled insights into your supply chain operations. This enhances operational transparency, aids in rapid decision-making, and can significantly reduce the risk of costly recalls. In addition, the detailed analytics provided by GS1 Digital Link empower you to use data to anticipate potential issues and address them proactively, thus safeguarding your brand's reputation and integrity. In essence, BL.INK’s GS1 Digital Link solution not only streamlines your packaging process but also turns your packaging into an interactive portal between your products and your consumers. It builds deeper trust and engagement, ensuring that your products are not only compliant but also ahead of industry standards in terms of traceability and consumer safety.

Connect with BL.INK as you start your GS1 Digital link journey.