Listen to this blog

Harnessing the Power of 2D Barcodes for Supply Chain Data

In the ever-evolving landscape of supply chain management, innovation is the driving force behind increased efficiency, accuracy, and transparency. One such innovation that has revolutionized the industry is the use of 2D barcodes for supply chain data. These barcodes have become a linchpin in the quest for seamless operations, providing unparalleled benefits to manufacturers, distributors, retailers, and even consumers. In this blog, we'll explore how 2D barcodes—also called GS1 Digital Link—are transforming supply chains and why they are essential for modern logistics.

The Rise of 2D Barcodes in Supply Chain Management

2D barcodes are not just an upgrade from their 1D predecessors; they are a game-changer. Unlike 1D barcodes, which store information in a linear fashion, 2D barcodes encode data both horizontally and vertically, allowing them to store much more information in a compact space. This capability is crucial in supply chain management, where the need for detailed and accessible information is paramount.

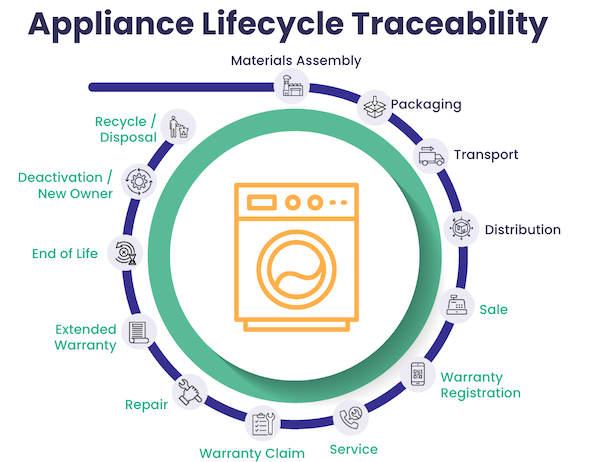

2D barcodes can include a product's Global Trade Item Number (GTIN), batch or lot number, serial number, expiration date—and much, much more. This wealth of information can be accessed with a single scan, providing supply chain partners with all the data they need to manage inventory, track shipments, and ensure product authenticity. Moreover, 2D barcodes can direct users to dynamic website pages or microsites that provide the most current information, enhancing engagement and transparency. BL.INK recently announced BL.INK CXP, a no-code mobile microsite CMS that orchestrates millions of data points into dynamic product microsites all the way down to the product's serial number, if needed.

Enhancing Efficiency and Reducing Errors

One of the standout benefits of using 2D barcodes for supply chain data is the significant boost in efficiency. As products travel on conveyor belts, scanners can read 2D barcodes from any direction, reducing the time and effort required to position items correctly. This omnidirectional readability increases the speed of operations and minimizes human error, ensuring that products are accurately tracked and managed throughout the supply chain.

The ability to scan 2D barcodes quickly and accurately also means that inventory management becomes more streamlined. Workers can instantly access detailed product information, making it easier to pack boxes correctly, route items to the right locations, and manage stock levels. This level of precision reduces the likelihood of mistakes and ensures that the right products reach the right destinations in a timely manner.

Improving Transparency and Compliance

In an era where regulatory compliance and consumer trust are critical, the transparency provided by 2D barcodes is invaluable. For industries such as food and pharmaceuticals, where safety and traceability are paramount, 2D barcodes offer granular visibility into the supply chain. This visibility helps companies meet regulatory requirements, such as the FDA’s Food Safety Modernization Act, by enabling efficient product tracing and recall management.

With 2D barcodes, companies can quickly trace products back through the supply chain, identifying the source of any issues and taking swift action to mitigate risks. This capability not only protects consumers but also enhances a company's reputation by demonstrating a commitment to safety and quality.

Cost-Effective Solutions for Modern Supply Chains

Cost efficiency is a cornerstone of successful supply chain management, and 2D barcodes excel in this area. While RFID tags offer some of the same benefits, they come with a higher price tag and are less durable. In contrast, 2D barcodes are affordable and robust, making them an ideal solution for a wide range of applications.

The cost of implementing 2D barcode scanning technology has decreased significantly over the years. Modern scanners are more affordable and come with advanced features that enhance their utility. Additionally, the cost of printing barcode labels is minimal, making it a cost-effective option for businesses of all sizes.

By reducing the need for manual labor and minimizing errors, 2D barcodes help companies maintain their bottom line. Automated scanning systems streamline operations, reducing labor costs and increasing productivity. As labor costs continue to rise, the savings provided by 2D barcode technology become even more significant.

Advantages Over RFID Tags

While RFID tags have their place in supply chain management, they are not always the best choice. RFID technology requires a significant investment, and the tags themselves can be prone to damage during transit. This vulnerability can render them useless at critical moments, compromising the flow of information.

In contrast, 2D barcodes are highly durable and can withstand the rigors of the supply chain environment. Their ability to be read from any direction makes them more versatile and reliable. Furthermore, the lower cost of 2D barcode implementation makes them a more accessible option for many businesses.

Engaging Consumers and Supply Chain Partners

2D barcodes are not just tools for internal operations; they also enhance engagement with consumers and supply chain partners. For consumers, scanning a 2D barcode on a product can provide instant access to detailed information about the item, including its origin, ingredients, and expiration date. This transparency builds trust and empowers consumers to make informed choices.

Supply chain partners benefit from the ease of accessing real-time data through 2D barcodes. Whether at the manufacturing stage, during transit, or at the point of sale, partners can quickly obtain the information they need to ensure smooth operations. This interconnectedness fosters collaboration and improves overall supply chain performance.

Real-World Applications and Success Stories

The adoption of 2D barcodes for supply chain data is not just theoretical; it is happening in real-world scenarios with impressive results. For example, a leading food manufacturer implemented 2D barcodes to improve traceability and compliance. By encoding detailed product information in 2D barcodes, the company enhanced its ability to track products through the supply chain, manage recalls efficiently, and meet regulatory requirements.

Another success story comes from the pharmaceutical industry, where a major distributor used 2D barcodes to enhance inventory management. The ability to scan 2D barcodes from any direction reduced the time required for inventory checks and improved accuracy. This led to a more efficient distribution process and better customer satisfaction.

Embracing the Future with BL.INK

At BL.INK, we understand the transformative potential of 2D barcodes for supply chain data. Our cutting-edge solutions are designed to help businesses harness this technology to achieve greater efficiency, accuracy, and transparency. By integrating 2D barcodes into your supply chain operations, you can stay ahead of the curve and meet the demands of today's dynamic market.

We’re here to help brands prepare for Sunrise 2027 GS1 Digital Link. We combine GS1-compliant, validated links in our enterprise link management platform with QR codes that last 50+ years and lead to dynamic, individual product microsites. We integrate millions of data points, which generally live in silos within organizations, to power perfectly compliant links and microsites. And you can go live in weeks, not years.

Our platform offers seamless integration with existing systems, enabling you to start reaping the benefits of 2D barcodes without disrupting your operations. Whether you are looking to improve inventory management, enhance traceability, or engage consumers with dynamic product information, BL.INK has the tools you need to succeed.

Ready for the promise of 2D barcodes?

The future of supply chain management lies in leveraging advanced technologies that provide detailed, accessible, and actionable data. 2D barcodes for supply chain data are at the forefront of this revolution, offering a cost-effective, reliable, and versatile solution for businesses of all sizes. By embracing 2D barcodes, companies can enhance efficiency, improve accuracy, and build greater transparency into their operations, ultimately leading to better outcomes for all stakeholders. Explore the possibilities with BL.INK and take your supply chain to the next level. Schedule time to meet with BL.INK!